Winter can be unpredictable, but there’s one thing we know for sure: Winter is tough on lumber. Cold temperatures, dry indoor heat, and fluctuating humidity create a perfect storm for lumber cracking, warping, shrinking, and swelling. That’s bad news for product quality and profits.

But it’s not all doom and gloom! At Rex Lumber, we understand how environmental shifts affect wood, and we help customers get out in front of seasonal changes to protect their inventory during harsh winter months.

Today, we’re taking a look at everything you need to know about winter lumber movement, plus how to keep your inventory safe, protected, and ready to sell.

What Causes Lumber Movement, and Why It Gets Worse in Winter

“Lumber movement” is the natural expansion and contraction of wood as it releases or absorbs moisture. Wood is hygroscopic, meaning it constantly attempts to match the moisture level of its surrounding environment.

During winter, this process is more extreme because:

During winter, this process is more extreme because:

- Indoor heating dries out the air. As moisture levels drop, lumber releases moisture to keep balanced. This can lead to cracking, shrinkage, or joint separation.

- Cold outdoor air creates rapid fluctuations in moisture. Boards can experience big temperature and humidity differences throughout any given day.

- Poor ventilation traps dry air around lumber. Especially in tightly stacked bundles, poor ventilation can cause uneven drying.

Each of these issues can cause big problems, leading to callbacks, customer complaints, and inventory loss. Fortunately, there are some practical ways to protect your lumber supply and keep customers happy this winter.

But first, let’s look at some critical numbers.

Why 6–8% Moisture Content and 40–50% Humidity Are So Important

Not sure what “ideal conditions” really mean? Here are the two benchmarks that keep lumber happy and stable.

6–8% Moisture Content: The Sweet Spot

Wood naturally seeks equilibrium. When you store lumber at a 6-8% moisture content, it can remain balanced with typical indoor conditions where the products will eventually be used.

This helps prevent:

- Warping

- Cupping

- Cracking

- Gaps after installation

In short: 6–8% Moisture Content = acclimated, stable, ready-to-sell wood.

40–50% Relative Humidity: The Ideal Storage Environment

If the humidity is too high, wood absorbs moisture and swells. On the other hand, if the humidity is too low, wood loses moisture and shrinks. Maintaining 40-50% Relative Humidity supports stable inventory and happy customers by keeping the surrounding air “in sync” with the target 6-8% moisture content.

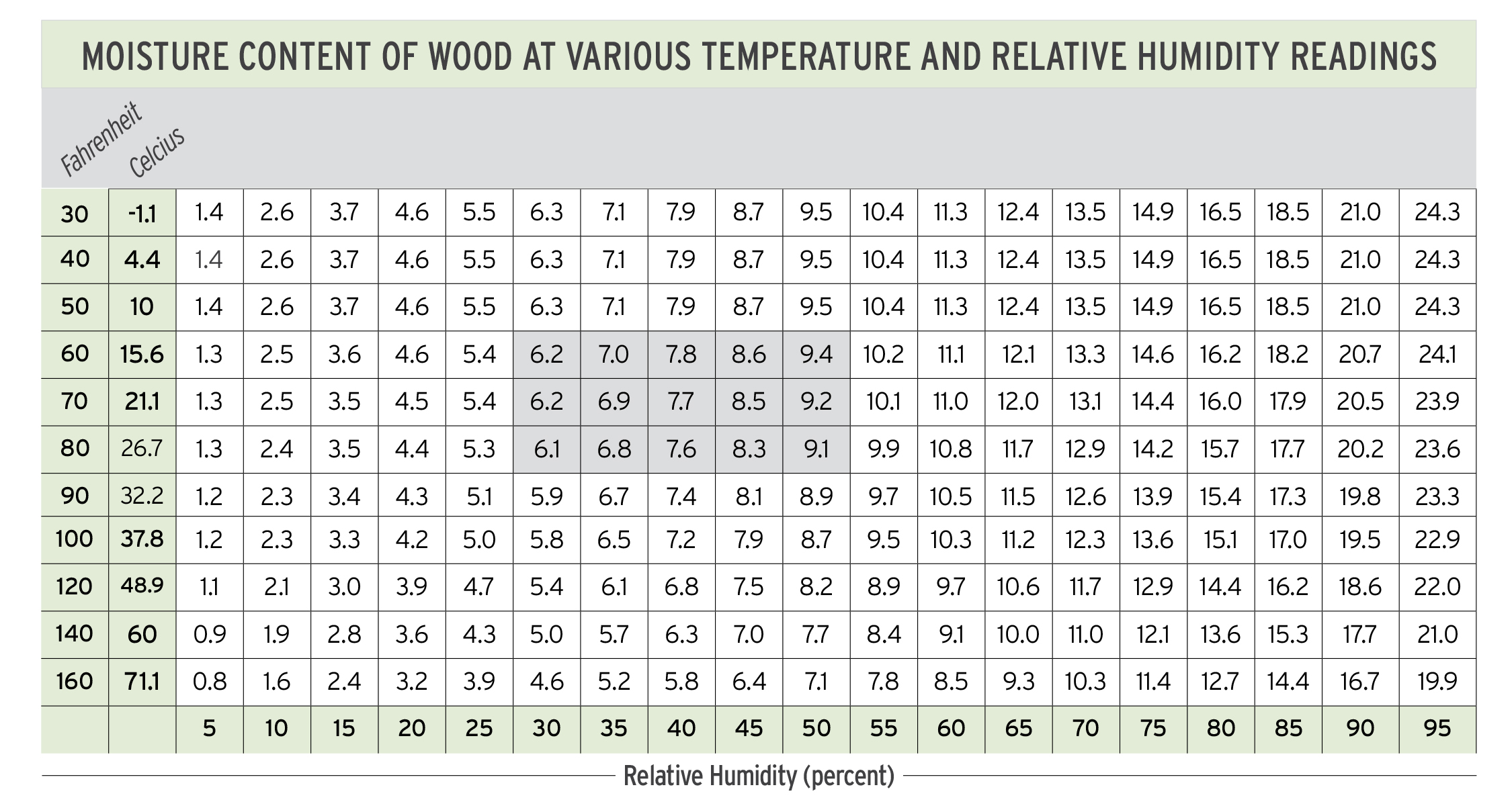

Most hardwoods are used in an interior application and will reach their equilibrium moisture content of 6-9% at 60 – 80 degrees and 30 – 50% relative humidity. These are normal living conditions, where we keep our indoor environments and are most comfortable. See the following chart to indicate the equilibrium moisture content (EMC) for any given combination of relative humidity and temperature.

Best Practices to Protect Your Lumber Inventory This Winter

Winter creates the “perfect conditions” for lumber movement, but you’re not at the mercy of the elements. The more control you have over your storage environment, the more stable your inventory stays.

Below, we examine four core practices that any retailer can follow to minimize shrinkage, cracking, warping, and inventory loss during the cold winter months.

Monitor and Control Humidity

Monitor and Control Humidity

One of the most critical steps in preventing winter lumber movement is maintaining stable humidity levels. Wood constantly exchanges moisture with the surrounding air, so even a slight drop in relative humidity can trigger shrinking.

Staying proactive with humidity is one of the easiest ways to protect inventory:

- Keep storage spaces between 40–50% RH.

- Use hygrometers to monitor indoor conditions.

- Install humidifiers or dehumidifiers when needed.

- Remember: even small swings in humidity can cause noticeable lumber movement.

Store Lumber Correctly to Improve Airflow

Good airflow keeps the moisture inside your lumber evenly distributed. On the other hand, poor storage setups can cause localized drying, resulting in checking, cupping, or uneven shrinkage. Proper airflow is always essential, but becomes even more critical during cold winter months.

- Use raised supports to keep boards off cold concrete.

- Place spacers (stickers) evenly between layers.

- Avoid stacking lumber too tightly or directly against exterior walls.

- Keep aisles open for air circulation.

Maintain Stable Temperatures

Temperature swings directly affect how wood gains or loses moisture. Sudden heating or cooling causes wood to react faster than it can stabilize, which increases the risk of movement. When you maintain a consistent storage space temperature, you protect your inventory from unpredictable elements and keep it ready for sale.

Remember to:

- Avoid rapid heating or cooling of storage spaces.

- Insulate warehouses or rack areas whenever possible.

- Radiant heat systems help maintain consistent conditions.

Rotate Inventory Seasonally

Rotate Inventory Seasonally

Lumber that sits untouched through the winter can gradually lose moisture, making it more vulnerable to shrinkage. Fortunately, regular rotation can help reduce prolonged exposure to dry or rapidly fluctuating environments. Rotating also makes it easier to spot changes early on before it’s too late.

You can rotate inventory like this:

- Move older stock forward to reduce exposure time.

- Inspect boards regularly for early signs of movement.

- Perform light re-stacking or flipping when needed.

- Document any changes in MC (moisture content) or RH (relative humidity)

Protecting Your Specialty Products (Flooring, Moulding & Millwork)

Precision-milled products are particularly susceptible to changes in moisture levels.

Try to always:

- Store finished materials in climate-controlled areas.

- Provide customers with clear guidance on acclimation before installation.

- Proactively educating buyers reduces callbacks, returns, and service issues.

Rex Lumber’s kiln-drying and controlled storage processes ensure these products start in the proper condition; then, it’s up to you to preserve them.

Partner with a Supplier That Protects Your Inventory from Day One

Winter lumber movement doesn’t have to impact your margins negatively. With proper storage, humidity control, and frequent monitoring, you can protect your lumber in every season.

Rex Lumber kiln-dries and stores lumber correctly year-round, delivering product with the ideal moisture levels and stability. When you partner with a supplier that understands the science behind wood movement, your inventory stays stronger and your customers stay happy.

Contact Rex Lumber today to learn more about kiln-drying services, best practices for winter storage, and how we help retailers prevent lumber movement all year long.